Polydopamine Nanocoating Technologies in 2025: Transforming Surface Science and Industry with Rapid Innovation. Explore Market Growth, Disruptive Applications, and the Future of Advanced Coatings.

- Executive Summary: Key Insights & 2025 Highlights

- Market Overview: Defining Polydopamine Nanocoating Technologies

- Current Market Size & 2025 Forecast (CAGR 2025–2030: ~18%)

- Key Drivers: Biomedical, Electronics, and Energy Applications

- Technology Landscape: Innovations, Patents, and R&D Trends

- Competitive Analysis: Leading Players & Emerging Startups

- Regulatory Environment & Standards

- Challenges and Barriers to Adoption

- Future Outlook: Disruptive Trends and Market Opportunities (2025–2030)

- Strategic Recommendations for Stakeholders

- Sources & References

Executive Summary: Key Insights & 2025 Highlights

Polydopamine (PDA) nanocoating technologies are rapidly emerging as a transformative solution across diverse industries, driven by their unique ability to form conformal, adhesive, and functional coatings on virtually any substrate. In 2025, the field is witnessing accelerated adoption, propelled by advances in scalable synthesis, surface engineering, and integration with other nanomaterials. Key insights reveal that PDA’s biocompatibility, chemical versatility, and ease of deposition are enabling breakthroughs in biomedical devices, energy storage, water purification, and advanced manufacturing.

A major highlight for 2025 is the commercialization of next-generation PDA nanocoatings with tunable thickness, enhanced stability, and tailored surface functionalities. Leading research institutions and industry players, such as Massachusetts Institute of Technology and BASF SE, are pioneering scalable production methods that reduce costs and environmental impact. These innovations are making PDA coatings more accessible for high-value applications, including implantable medical devices, anti-fouling surfaces, and flexible electronics.

The integration of PDA with other nanomaterials—such as graphene, metal nanoparticles, and polymers—is another key trend, enabling multifunctional surfaces with enhanced conductivity, antimicrobial properties, and selective adsorption capabilities. Regulatory bodies, including the U.S. Food and Drug Administration, are increasingly providing guidance for the safe use of PDA-coated products in healthcare, further accelerating market entry and adoption.

Looking ahead, 2025 is set to be a pivotal year for PDA nanocoating technologies, with anticipated growth in both research activity and commercial deployment. Strategic collaborations between academia and industry, exemplified by partnerships involving DuPont and Samsung Electronics, are expected to drive innovation and expand the application landscape. As sustainability and performance demands intensify, PDA nanocoatings are positioned to play a central role in next-generation surface engineering solutions.

Market Overview: Defining Polydopamine Nanocoating Technologies

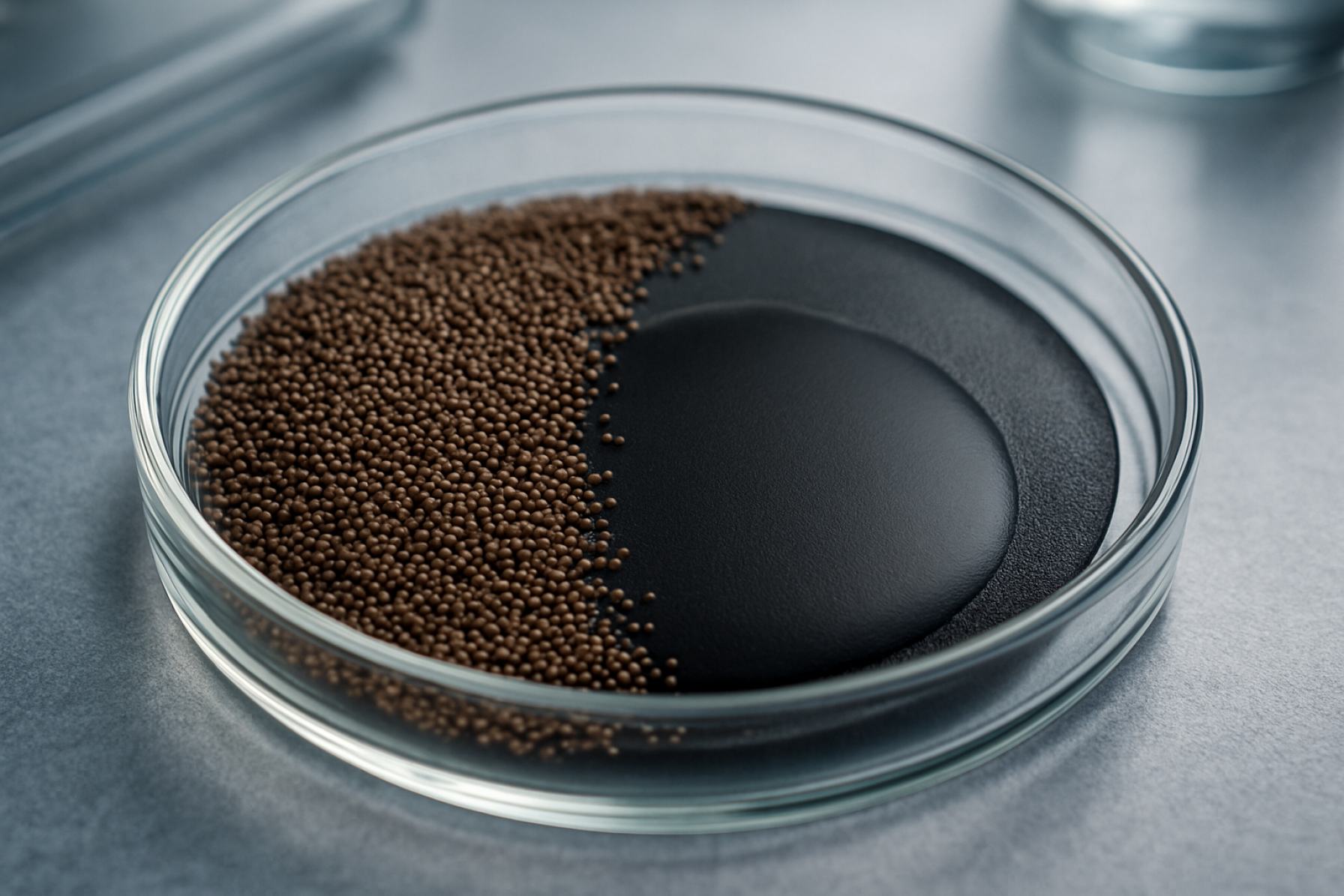

Polydopamine (PDA) nanocoating technologies represent a rapidly evolving segment within the advanced materials market, characterized by their unique ability to form conformal, adhesive, and functional thin films on a wide variety of substrates. Inspired by the adhesive proteins found in mussel byssus, polydopamine coatings are synthesized through the oxidative self-polymerization of dopamine under mild, aqueous conditions. This process results in a versatile nanocoating that can be applied to metals, polymers, ceramics, and even biological materials, offering a platform for further functionalization and surface modification.

The market for polydopamine nanocoating technologies is driven by their broad applicability across sectors such as biomedical devices, energy storage, water treatment, and electronics. In the biomedical field, PDA coatings are valued for their biocompatibility and ability to immobilize biomolecules, making them suitable for drug delivery systems, implantable devices, and biosensors. In energy and environmental applications, PDA’s strong adhesion and chemical reactivity enable the development of advanced membranes, corrosion-resistant surfaces, and functional electrodes.

Key industry players and research institutions are actively advancing the commercialization and scalability of PDA nanocoating processes. For example, DSM and BASF SE are exploring PDA-based surface treatments for medical and industrial applications, while academic collaborations continue to expand the understanding of PDA’s polymerization mechanisms and functionalization strategies. The technology’s compatibility with green chemistry principles—owing to its water-based synthesis and minimal use of toxic reagents—further enhances its appeal in markets increasingly focused on sustainability.

Looking ahead to 2025, the polydopamine nanocoating market is expected to benefit from ongoing innovations in nanomaterial engineering and surface science. The integration of PDA coatings with other nanomaterials, such as graphene or metal nanoparticles, is anticipated to unlock new functionalities and performance characteristics. As regulatory frameworks evolve and end-user industries demand more robust, multifunctional coatings, polydopamine nanocoating technologies are poised to play a pivotal role in next-generation surface engineering solutions.

Current Market Size & 2025 Forecast (CAGR 2025–2030: ~18%)

The global market for polydopamine (PDA) nanocoating technologies has experienced robust growth in recent years, driven by increasing demand across biomedical, electronics, energy, and environmental sectors. As of 2025, the market size is estimated to be in the range of several hundred million USD, with North America, Europe, and East Asia representing the largest regional markets. This expansion is attributed to the unique properties of PDA nanocoatings, such as strong adhesion to diverse substrates, biocompatibility, and ease of functionalization, which have enabled their adoption in applications ranging from drug delivery systems to anti-corrosion coatings and biosensors.

Key industry players, including BioTek Instruments, BASF SE, and DSM, have invested in research and development to enhance the scalability and performance of PDA-based coatings. The biomedical sector, in particular, has seen rapid uptake due to the material’s ability to improve implant integration and reduce infection risks. Meanwhile, electronics manufacturers are leveraging PDA nanocoatings for surface modification and improved device longevity.

Looking ahead, the market is forecasted to grow at a compound annual growth rate (CAGR) of approximately 18% from 2025 to 2030. This projection is underpinned by ongoing advancements in nanotechnology, increased regulatory support for biocompatible materials, and the rising need for sustainable surface engineering solutions. The Asia-Pacific region is expected to witness the fastest growth, fueled by expanding manufacturing capabilities and government initiatives supporting nanomaterials research.

Despite the optimistic outlook, challenges such as high production costs and the need for standardized quality control remain. However, collaborative efforts between academia, industry, and regulatory bodies—such as those led by International Organization for Standardization (ISO)—are expected to address these barriers, further accelerating market adoption. As a result, polydopamine nanocoating technologies are poised to become a cornerstone in next-generation surface engineering by the end of the decade.

Key Drivers: Biomedical, Electronics, and Energy Applications

Polydopamine (PDA) nanocoating technologies have rapidly advanced due to their unique versatility and bioinspired adhesive properties, enabling a wide range of applications across biomedical, electronics, and energy sectors. The key drivers for the adoption and development of PDA nanocoatings in these fields stem from their ability to form conformal, robust, and functional layers on virtually any substrate, under mild conditions.

In the biomedical sector, PDA nanocoatings are increasingly utilized for surface modification of implants, drug delivery systems, and biosensors. Their biocompatibility and ease of functionalization allow for the immobilization of biomolecules, enhancing cell adhesion, proliferation, and antibacterial properties. For example, PDA coatings are used to improve the hemocompatibility of cardiovascular stents and to facilitate the controlled release of therapeutic agents from implant surfaces. Leading research institutions and medical device manufacturers are actively exploring PDA-based strategies to address challenges in tissue engineering and regenerative medicine (National Institute of Biomedical Imaging and Bioengineering).

In electronics, PDA nanocoatings serve as versatile platforms for the fabrication of flexible and wearable devices. Their strong adhesion to diverse substrates, including metals, polymers, and ceramics, enables the integration of functional materials such as nanoparticles, conductive polymers, and quantum dots. This capability is critical for the development of next-generation sensors, flexible circuits, and energy storage devices. Companies in the electronics industry are leveraging PDA’s surface chemistry to enhance device performance and durability, particularly in harsh or variable environments (Samsung Electronics Co., Ltd.).

The energy sector also benefits from PDA nanocoating technologies, particularly in the areas of battery electrodes, supercapacitors, and solar cells. PDA’s redox-active nature and ability to chelate metal ions facilitate the synthesis of advanced electrode materials with improved conductivity, stability, and cycling performance. Additionally, PDA coatings are employed to enhance the interfacial properties of energy devices, leading to higher efficiency and longer operational lifespans. Major energy technology developers are incorporating PDA-based materials to address the growing demand for sustainable and high-performance energy solutions (Tesla, Inc.).

Overall, the convergence of biomedical, electronics, and energy applications is driving significant innovation in polydopamine nanocoating technologies, positioning them as a cornerstone for future multifunctional material systems.

Technology Landscape: Innovations, Patents, and R&D Trends

The technology landscape for polydopamine (PDA) nanocoating is rapidly evolving, driven by its unique adhesive properties, biocompatibility, and versatility across multiple industries. Since its initial discovery as a synthetic mimic of mussel adhesive proteins, PDA has become a cornerstone for surface modification in biomedical devices, energy storage, water treatment, and advanced materials. Recent innovations focus on refining deposition techniques, such as controlled self-polymerization, layer-by-layer assembly, and co-deposition with other functional materials, to enhance coating uniformity, thickness control, and functionalization capabilities.

Patent activity in the PDA nanocoating space has intensified, reflecting both academic and industrial interest. Major players, including DSM, BASF SE, and 3M Company, have filed patents covering novel synthesis methods, composite coatings, and applications in drug delivery, biosensors, and anti-fouling surfaces. Notably, patents are increasingly targeting hybrid nanocoatings that combine PDA with nanoparticles, polymers, or bioactive molecules to impart multifunctional properties such as antimicrobial activity, electrical conductivity, or enhanced mechanical strength.

Research and development trends indicate a shift toward scalable and environmentally friendly production methods. Academic institutions and research centers, such as Massachusetts Institute of Technology and Tsinghua University, are pioneering green chemistry approaches for PDA synthesis, minimizing the use of toxic solvents and reducing energy consumption. Additionally, there is a growing emphasis on in situ PDA coating processes that enable direct functionalization of complex substrates, including medical implants and flexible electronics, without compromising their structural integrity.

Emerging areas of innovation include stimuli-responsive PDA coatings that change properties in response to pH, temperature, or light, opening new possibilities for smart drug delivery systems and adaptive materials. Furthermore, the integration of PDA nanocoatings with digital manufacturing techniques, such as 3D printing, is being explored to create customized, multifunctional surfaces for next-generation devices.

Overall, the PDA nanocoating technology landscape in 2025 is characterized by robust patent activity, interdisciplinary R&D collaborations, and a clear trajectory toward sustainable, high-performance coatings tailored for advanced industrial and biomedical applications.

Competitive Analysis: Leading Players & Emerging Startups

The polydopamine (PDA) nanocoating sector has witnessed significant advancements, with both established companies and innovative startups driving the field forward. Leading players have leveraged PDA’s unique adhesive and functionalization properties to develop solutions for biomedical devices, energy storage, water treatment, and surface engineering.

Among the established entities, BioTek Instruments (now part of Agilent Technologies) has integrated PDA coatings into their microplate technologies, enhancing biomolecule immobilization and assay sensitivity. Thermo Fisher Scientific Inc. has also explored PDA-based surface modifications for improved biosensor performance and cell culture applications. In the Asian market, Nitto Denko Corporation has developed PDA nanocoatings for advanced filtration membranes, targeting water purification and industrial separation processes.

Emerging startups are pushing the boundaries of PDA nanocoating applications. PolyNovo Limited has focused on biomedical uses, particularly in wound healing and implantable devices, utilizing PDA’s biocompatibility and tunable surface chemistry. NanoAndMore offers custom PDA-coated atomic force microscopy (AFM) probes, catering to research institutions and nanotechnology developers. Meanwhile, Surface Pharmaceuticals Inc. is exploring PDA coatings for drug delivery systems and ophthalmic applications, aiming to improve therapeutic efficacy and patient outcomes.

Collaborations between academia and industry are also shaping the competitive landscape. For instance, Evonik Industries AG has partnered with research institutes to develop PDA-based nanocomposites for next-generation energy storage devices. These partnerships accelerate the translation of laboratory-scale innovations into commercial products.

The competitive environment is further characterized by ongoing patent activity and proprietary process development, as companies seek to differentiate their offerings through enhanced coating uniformity, scalability, and functionalization options. As the market matures, the interplay between established leaders and agile startups is expected to drive both incremental improvements and disruptive breakthroughs in polydopamine nanocoating technologies.

Regulatory Environment & Standards

The regulatory environment for polydopamine (PDA) nanocoating technologies is evolving in response to their expanding applications in biomedical devices, water treatment, electronics, and surface engineering. As of 2025, regulatory oversight primarily focuses on the safety, biocompatibility, and environmental impact of PDA-coated products, especially in sectors where human exposure or ecological release is likely.

In the biomedical field, PDA nanocoatings are increasingly used for drug delivery systems, implantable devices, and biosensors. Regulatory agencies such as the U.S. Food and Drug Administration and the European Medicines Agency require comprehensive preclinical and clinical data to demonstrate the safety and efficacy of PDA-coated medical devices. This includes assessments of cytotoxicity, immunogenicity, and long-term stability. The biocompatibility of PDA, derived from its similarity to natural melanin, often facilitates regulatory approval, but each application is evaluated on a case-by-case basis.

For environmental and industrial applications, such as water purification membranes and anti-corrosive coatings, regulatory standards are shaped by organizations like the U.S. Environmental Protection Agency and the European Chemicals Agency. These bodies assess the potential release of nanomaterials into the environment, requiring data on degradation, persistence, and ecotoxicity. Manufacturers must comply with chemical registration and notification requirements, such as REACH in the European Union, which mandates detailed disclosure of material composition and potential hazards.

Internationally, the International Organization for Standardization (ISO) and the ASTM International are developing standards specific to nanomaterials, including those relevant to PDA coatings. These standards address terminology, characterization methods, and performance testing, aiming to harmonize safety and quality benchmarks across markets. For example, ISO/TS 80004 provides standardized definitions for nanotechnology, while ongoing efforts seek to establish protocols for evaluating the unique properties of PDA nanocoatings.

As PDA nanocoating technologies mature, regulatory frameworks are expected to become more nuanced, incorporating advances in risk assessment and lifecycle analysis. Stakeholders—including manufacturers, researchers, and regulators—are encouraged to engage in collaborative efforts to ensure that standards keep pace with innovation, safeguarding public health and the environment while supporting technological progress.

Challenges and Barriers to Adoption

Despite the promising potential of polydopamine (PDA) nanocoating technologies in fields such as biomedical devices, energy storage, and surface engineering, several challenges and barriers continue to hinder their widespread adoption. One of the primary technical challenges is the control over coating uniformity and thickness at the nanoscale. Achieving reproducible and defect-free coatings on complex geometries remains difficult, which can impact the performance and reliability of the final product. Additionally, the polymerization process of dopamine is highly sensitive to environmental factors such as pH, temperature, and oxygen concentration, making process standardization challenging for industrial-scale applications.

Another significant barrier is the scalability of PDA nanocoating processes. While laboratory-scale methods are well established, translating these protocols to large-scale manufacturing requires the development of cost-effective, high-throughput systems that maintain coating quality. The cost of dopamine precursors and the need for specialized equipment can further increase production expenses, limiting commercial viability for some applications.

From a regulatory perspective, the biocompatibility and long-term stability of PDA coatings, especially for medical and food-contact applications, require comprehensive evaluation. Regulatory bodies such as the U.S. Food and Drug Administration and the European Medicines Agency have stringent requirements for new materials, and the lack of extensive long-term data on PDA’s in vivo behavior can delay approvals and market entry.

Intellectual property (IP) concerns also pose a barrier, as the field is rapidly evolving and patent landscapes are becoming increasingly crowded. This can create uncertainty for companies seeking to commercialize new PDA-based products, as freedom-to-operate analyses become more complex.

Finally, there is a need for greater industry collaboration and standardization. Organizations such as the International Organization for Standardization are beginning to address nanomaterial standards, but specific guidelines for PDA coatings are still lacking. Without clear standards, end-users may be hesitant to adopt these technologies due to concerns about reproducibility, safety, and regulatory compliance.

Addressing these challenges will require coordinated efforts among researchers, manufacturers, and regulatory agencies to develop robust, scalable, and standardized PDA nanocoating solutions suitable for diverse industrial applications.

Future Outlook: Disruptive Trends and Market Opportunities (2025–2030)

The future outlook for polydopamine (PDA) nanocoating technologies between 2025 and 2030 is marked by disruptive trends and expanding market opportunities across multiple sectors. As a bioinspired material, PDA’s unique adhesive properties, biocompatibility, and ease of functionalization are driving its adoption in advanced applications, particularly in biomedical devices, energy storage, and environmental remediation.

One of the most significant trends is the integration of PDA nanocoatings in next-generation medical devices and drug delivery systems. The ability of PDA to form conformal coatings on virtually any substrate, combined with its capacity to immobilize biomolecules, is enabling the development of highly selective biosensors and implantable devices with improved biocompatibility and reduced immune response. Leading research institutions and companies are actively exploring PDA-based coatings for stents, catheters, and tissue engineering scaffolds, anticipating regulatory approvals and commercial launches in the latter half of the decade (Boston Scientific Corporation).

In the energy sector, PDA nanocoatings are poised to disrupt battery and supercapacitor manufacturing. Their role as conductive, protective, and functional interlayers is being leveraged to enhance electrode stability, increase charge/discharge rates, and extend device lifespans. Major battery manufacturers are investing in scalable PDA coating processes to meet the growing demand for high-performance energy storage solutions, particularly for electric vehicles and grid storage (Panasonic Corporation).

Environmental applications represent another high-growth area. PDA’s strong affinity for heavy metals and organic pollutants is being harnessed in water purification membranes and sensors. The push for sustainable, green technologies is expected to accelerate the adoption of PDA-based solutions in municipal and industrial water treatment systems (Veolia Environnement S.A.).

Looking ahead, the market is likely to see increased collaboration between material suppliers, device manufacturers, and end-users to develop tailored PDA nanocoating formulations. Advances in automation and process control will further reduce production costs, making PDA coatings accessible for mass-market applications. As intellectual property portfolios expand and regulatory frameworks mature, PDA nanocoating technologies are set to become a cornerstone of innovation in surface engineering and functional materials by 2030.

Strategic Recommendations for Stakeholders

As polydopamine (PDA) nanocoating technologies continue to advance, stakeholders across academia, industry, and regulatory bodies must adopt strategic approaches to maximize benefits and address emerging challenges. The following recommendations are tailored to key stakeholder groups involved in the development, commercialization, and regulation of PDA nanocoatings in 2025.

- For Research Institutions and Universities: Prioritize interdisciplinary collaborations that bridge materials science, biomedical engineering, and environmental science. This will accelerate the discovery of novel PDA-based composites and functionalizations, expanding application areas such as drug delivery, biosensing, and anti-fouling surfaces. Establishing partnerships with industry can also facilitate technology transfer and commercialization.

- For Manufacturers and Industrial Stakeholders: Invest in scalable and cost-effective synthesis methods for PDA nanocoatings, focusing on green chemistry principles to minimize environmental impact. Engage in pilot projects with end-users in sectors like healthcare, electronics, and energy to validate performance and durability under real-world conditions. Collaborate with standards organizations to help define quality benchmarks and testing protocols for PDA-coated products.

- For Regulatory Agencies: Develop clear guidelines for the safety assessment and environmental impact of PDA nanocoatings, particularly for biomedical and food-contact applications. Engage with scientific communities and industry leaders to ensure that regulations keep pace with technological advancements, while safeguarding public health and the environment. Agencies such as the U.S. Food and Drug Administration and the European Medicines Agency should consider establishing dedicated frameworks for nanomaterial-based coatings.

- For Investors and Funding Bodies: Support early-stage startups and research projects focused on PDA nanocoatings, especially those demonstrating clear pathways to commercialization and societal impact. Encourage the development of intellectual property portfolios and foster connections between innovators and potential industrial partners.

- For End-Users: Stay informed about the latest advancements in PDA nanocoating technologies and actively participate in pilot programs or collaborative research. Provide feedback to developers regarding performance, safety, and integration challenges to help guide future innovation.

By following these strategic recommendations, stakeholders can collectively drive the responsible development and adoption of polydopamine nanocoating technologies, ensuring their long-term success and societal benefit.

Sources & References

- Massachusetts Institute of Technology

- BASF SE

- DuPont

- DSM

- International Organization for Standardization (ISO)

- National Institute of Biomedical Imaging and Bioengineering

- Tsinghua University

- Thermo Fisher Scientific Inc.

- PolyNovo Limited

- NanoAndMore

- Surface Pharmaceuticals Inc.

- Evonik Industries AG

- European Medicines Agency

- European Chemicals Agency

- ASTM International

- Boston Scientific Corporation

- Veolia Environnement S.A.