Compliant Mechanisms in Precision Engineering Market Report 2025: In-Depth Analysis of Growth Drivers, Technology Innovations, and Global Opportunities. Explore Market Size, Leading Players, and Strategic Forecasts Through 2030.

- Executive Summary & Market Overview

- Key Technology Trends in Compliant Mechanisms

- Competitive Landscape and Leading Players

- Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

- Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Challenges, Risks, and Emerging Opportunities

- Future Outlook: Strategic Recommendations and Investment Insights

- Sources & References

Executive Summary & Market Overview

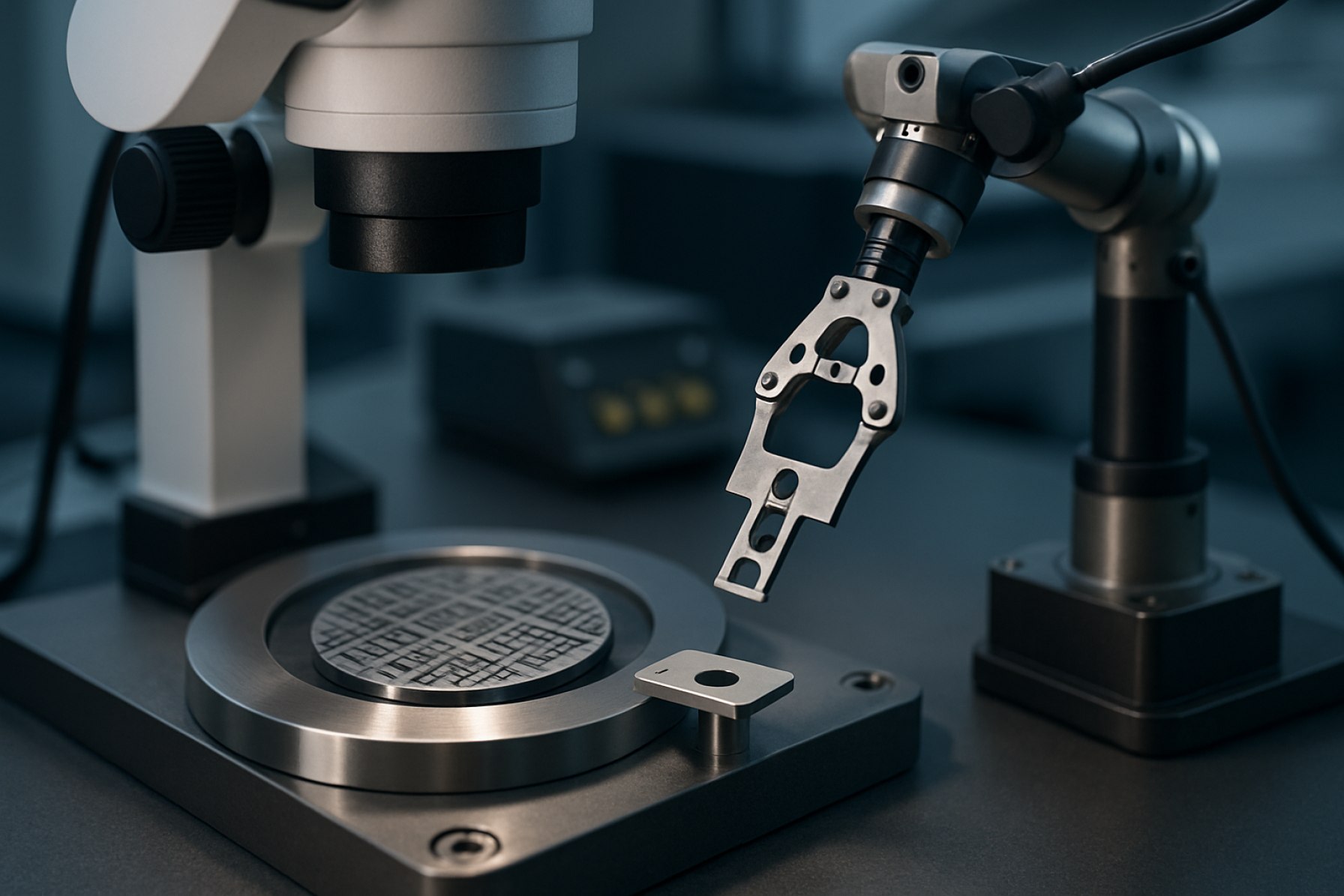

Compliant mechanisms are single-piece, flexible structures that achieve force and motion transmission through elastic deformation rather than traditional rigid-body joints. In precision engineering, these mechanisms are increasingly valued for their ability to deliver high accuracy, reduced friction, and minimal wear, making them ideal for applications in aerospace, medical devices, microelectromechanical systems (MEMS), and advanced manufacturing.

As of 2025, the global market for compliant mechanisms in precision engineering is experiencing robust growth, driven by the demand for miniaturized, reliable, and maintenance-free components. The integration of compliant mechanisms enables the design of lighter, more compact systems with fewer assembly steps and lower part counts, directly addressing the needs of industries focused on high-precision and high-reliability solutions. According to MarketsandMarkets, the precision engineering sector is projected to grow at a CAGR of over 6% through 2028, with compliant mechanisms representing a significant innovation vector within this space.

Key market drivers include:

- Advancements in additive manufacturing and microfabrication, which allow for the production of complex compliant structures previously unachievable with conventional machining (Society of Manufacturing Engineers).

- Increasing adoption in medical devices, where compliant mechanisms enable minimally invasive surgical tools and implantable devices with enhanced reliability and biocompatibility (U.S. Food & Drug Administration).

- Growing use in aerospace and optics, where precision, weight reduction, and vibration isolation are critical (NASA).

Regionally, North America and Europe lead in both research and commercialization, supported by strong investments in R&D and a mature precision engineering ecosystem. Asia-Pacific is rapidly emerging, fueled by expanding manufacturing capabilities and government initiatives supporting advanced engineering technologies (Statista).

In summary, compliant mechanisms are reshaping the landscape of precision engineering by enabling innovative designs that meet the stringent demands of next-generation applications. The market outlook for 2025 and beyond is positive, with continued technological advancements and cross-industry adoption expected to drive further growth.

Key Technology Trends in Compliant Mechanisms

Compliant mechanisms are increasingly pivotal in precision engineering, where the demand for high accuracy, miniaturization, and reliability is driving innovation. Unlike traditional mechanisms that rely on discrete joints and rigid-body motion, compliant mechanisms achieve motion through the elastic deformation of their constituent materials. This enables smoother, backlash-free movement, reduced part count, and enhanced repeatability—qualities essential for precision applications in fields such as optics, micro-electromechanical systems (MEMS), and biomedical devices.

In 2025, several key technology trends are shaping the adoption and advancement of compliant mechanisms in precision engineering:

- Advanced Materials: The integration of high-performance polymers, shape memory alloys, and advanced composites is expanding the design space for compliant mechanisms. These materials offer superior fatigue resistance, flexibility, and environmental stability, enabling mechanisms to operate reliably in demanding precision environments. For instance, the use of titanium alloys in compliant flexures for optical alignment systems is gaining traction due to their high strength-to-weight ratio and corrosion resistance (The Minerals, Metals & Materials Society).

- Topology Optimization and Additive Manufacturing: The synergy between computational design tools and additive manufacturing is revolutionizing the fabrication of compliant mechanisms. Topology optimization algorithms allow engineers to design highly efficient, monolithic structures tailored for specific motion profiles and load conditions. Additive manufacturing, particularly micro-3D printing, enables the realization of these complex geometries at micro and nano scales, which is critical for MEMS and precision instrumentation (American Society of Mechanical Engineers).

- Integration with Sensing and Actuation: Embedding sensors and actuators directly into compliant structures is a growing trend, facilitating real-time feedback and adaptive control. This integration is particularly valuable in applications such as surgical robotics and precision metrology, where sub-micron accuracy and dynamic response are required (IEEE).

- Simulation and Digital Twins: The adoption of advanced simulation tools and digital twin technology is enhancing the predictability and reliability of compliant mechanism designs. Engineers can now model the nonlinear elastic behavior and fatigue life of mechanisms under real-world conditions, reducing prototyping cycles and accelerating time-to-market (ANSYS).

These trends underscore the growing role of compliant mechanisms in pushing the boundaries of precision engineering, enabling new levels of performance, integration, and miniaturization across high-tech industries.

Competitive Landscape and Leading Players

The competitive landscape for compliant mechanisms in precision engineering is characterized by a blend of established multinational corporations, specialized engineering firms, and innovative startups. As of 2025, the market is witnessing increased activity due to the growing demand for miniaturized, high-precision components in sectors such as aerospace, medical devices, optics, and micro-electromechanical systems (MEMS).

Key players in this space include Flexure Engineering, which has established itself as a leader in the design and manufacturing of flexure-based compliant mechanisms for high-precision applications. Their solutions are widely adopted in semiconductor manufacturing and scientific instrumentation, where sub-micron accuracy is critical. Another significant player is Physik Instrumente (PI), renowned for its piezo-based nanopositioning systems that leverage compliant mechanisms to achieve frictionless, backlash-free motion.

In the medical device sector, Parker Hannifin and Boston Micromachines Corporation are notable for integrating compliant mechanisms into minimally invasive surgical tools and adaptive optics, respectively. These companies focus on leveraging the inherent advantages of compliant mechanisms—such as reduced part count, increased reliability, and enhanced precision—to meet stringent regulatory and performance requirements.

Startups and research-driven firms are also shaping the competitive landscape. MicroSure is pioneering the use of compliant mechanisms in microsurgical robotics, while Carl Zeiss AG continues to invest in compliant mechanism research for next-generation optical systems. Academic collaborations and technology transfer agreements are common, with institutions like Massachusetts Institute of Technology (MIT) and ETH Zurich contributing to the commercialization of novel compliant mechanism designs.

- Market competition is intensifying as end-users demand higher performance and reliability, driving innovation in materials (e.g., advanced alloys, polymers) and manufacturing techniques (e.g., additive manufacturing, microfabrication).

- Strategic partnerships and acquisitions are prevalent, with larger firms acquiring niche players to expand their technology portfolios and market reach.

- Intellectual property (IP) plays a crucial role, with leading companies holding extensive patents on compliant mechanism architectures and fabrication methods.

Overall, the competitive landscape in 2025 is defined by rapid technological advancement, cross-sector collaboration, and a focus on delivering precision-engineered solutions that leverage the unique benefits of compliant mechanisms.

Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

The market for compliant mechanisms in precision engineering is poised for robust growth between 2025 and 2030, driven by increasing demand for miniaturized, high-precision components across sectors such as aerospace, medical devices, and micro-electromechanical systems (MEMS). According to projections from MarketsandMarkets, the global compliant mechanisms market is expected to register a compound annual growth rate (CAGR) of approximately 8.2% during this period. This growth is underpinned by advancements in additive manufacturing, material science, and the integration of compliant mechanisms into next-generation precision instruments.

Revenue analysis indicates that the market, valued at around USD 1.1 billion in 2025, is forecasted to reach nearly USD 1.8 billion by 2030. This expansion is attributed to the increasing adoption of compliant mechanisms in high-value applications, particularly in surgical robotics, optical alignment systems, and precision motion control devices. The Asia-Pacific region is anticipated to exhibit the fastest growth, with countries like China, Japan, and South Korea investing heavily in precision manufacturing infrastructure and R&D, as highlighted by Grand View Research.

In terms of volume, the number of compliant mechanism-based components produced is expected to grow at a CAGR of 9.1% from 2025 to 2030. This surge is facilitated by the proliferation of 3D printing and microfabrication techniques, which enable cost-effective, high-volume production of complex, monolithic structures. The medical device segment, in particular, is projected to account for a significant share of this volume growth, as compliant mechanisms offer unique advantages in minimally invasive instruments and implantable devices, according to Frost & Sullivan.

- CAGR (2025–2030): ~8.2%

- Revenue (2025): USD 1.1 billion

- Revenue (2030): USD 1.8 billion

- Volume CAGR (2025–2030): ~9.1%

Overall, the market outlook for compliant mechanisms in precision engineering remains highly positive, with technological innovation and expanding end-use applications serving as primary growth catalysts. Strategic investments in R&D and manufacturing capabilities are expected to further accelerate market expansion through 2030.

Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

The regional market landscape for compliant mechanisms in precision engineering is shaped by varying levels of technological advancement, industry adoption, and research intensity across North America, Europe, Asia-Pacific, and the Rest of the World (RoW). Each region demonstrates unique drivers and challenges influencing the adoption and growth of compliant mechanisms in sectors such as aerospace, medical devices, robotics, and micro-electromechanical systems (MEMS).

- North America: North America, led by the United States, remains at the forefront of compliant mechanism innovation, driven by robust R&D investments and a strong presence of leading aerospace and medical device manufacturers. The region benefits from collaborations between academic institutions and industry, fostering rapid prototyping and commercialization. According to Grand View Research, the U.S. precision engineering market is expected to see steady growth through 2025, with compliant mechanisms gaining traction due to their ability to reduce part count and improve reliability in high-precision applications.

- Europe: Europe’s market is characterized by a focus on high-quality manufacturing and sustainability. Countries such as Germany, Switzerland, and the Netherlands are notable for their advanced precision engineering sectors, particularly in medical technology and microfabrication. The European Union’s emphasis on innovation and green manufacturing practices further supports the integration of compliant mechanisms, as highlighted by European Commission research initiatives. The region also benefits from a strong network of SMEs specializing in niche applications of compliant mechanisms.

- Asia-Pacific: The Asia-Pacific region is experiencing the fastest growth, propelled by expanding electronics, automotive, and robotics industries in China, Japan, and South Korea. Increased government funding for advanced manufacturing and the proliferation of precision engineering startups are accelerating the adoption of compliant mechanisms. Mordor Intelligence reports that Asia-Pacific’s share of the global precision engineering market is expected to rise significantly by 2025, with compliant mechanisms being integrated into next-generation MEMS and consumer electronics.

- Rest of World (RoW): In regions such as Latin America, the Middle East, and Africa, adoption remains nascent but is gradually increasing, particularly in sectors like oil & gas and emerging medical device manufacturing. Market growth is hindered by limited local expertise and infrastructure, but international partnerships and technology transfer initiatives are beginning to bridge these gaps, as noted by OECD reports on global innovation diffusion.

Overall, while North America and Europe lead in innovation and application, Asia-Pacific is rapidly closing the gap through aggressive industrial expansion, and RoW regions are poised for gradual uptake as global knowledge and technology dissemination continue.

Challenges, Risks, and Emerging Opportunities

Compliant mechanisms in precision engineering offer significant advantages, such as reduced part count, frictionless motion, and enhanced reliability. However, their adoption in high-precision applications faces several challenges and risks, even as new opportunities emerge in 2025.

One of the primary challenges is the complexity of design and analysis. Unlike traditional mechanisms, compliant mechanisms rely on elastic deformation, making their behavior highly nonlinear and sensitive to material properties and geometric variations. This necessitates advanced simulation tools and multidisciplinary expertise, which can increase development time and costs. Additionally, the lack of standardized design methodologies and limited availability of off-the-shelf compliant components further complicate integration into existing precision systems (ASME).

Material selection poses another significant risk. Precision engineering applications often demand high fatigue resistance, dimensional stability, and minimal creep. Many compliant mechanisms are fabricated from polymers or metals that may not meet these stringent requirements over extended operational lifetimes, especially in harsh environments such as aerospace or medical devices (SME). Furthermore, manufacturing tolerances for compliant structures are often tighter than for rigid-body mechanisms, increasing the risk of performance degradation due to process variability.

Emerging opportunities are driven by advances in additive manufacturing and smart materials. Additive manufacturing enables the fabrication of complex, monolithic compliant structures that were previously unachievable with traditional subtractive methods. This not only reduces assembly steps but also allows for the integration of multi-functional features, such as embedded sensors or actuators, directly into the mechanism (Stratasys). The development of shape-memory alloys and piezoelectric materials further expands the functional range of compliant mechanisms, enabling adaptive and self-sensing capabilities in precision systems (Nature Reviews Materials).

- Challenge: Nonlinear behavior and complex modeling requirements

- Risk: Material limitations affecting long-term reliability

- Opportunity: Additive manufacturing for complex, integrated designs

- Opportunity: Smart materials for adaptive and multifunctional mechanisms

In summary, while compliant mechanisms present unique challenges and risks in precision engineering, ongoing technological advancements are unlocking new opportunities for innovation and market growth in 2025.

Future Outlook: Strategic Recommendations and Investment Insights

The future outlook for compliant mechanisms in precision engineering is shaped by rapid advancements in materials science, additive manufacturing, and the growing demand for miniaturized, high-performance devices. As industries such as aerospace, medical devices, and micro-electromechanical systems (MEMS) increasingly seek solutions that offer reduced part count, enhanced reliability, and lower maintenance, compliant mechanisms are poised for significant adoption and innovation through 2025 and beyond.

Strategic Recommendations:

- Invest in Advanced Materials: Companies should prioritize R&D in high-performance polymers, shape-memory alloys, and composite materials. These materials enable compliant mechanisms to achieve greater flexibility, fatigue resistance, and integration into harsh environments, as highlighted by Sandvik and DuPont.

- Leverage Additive Manufacturing: The adoption of 3D printing and microfabrication techniques allows for the creation of complex, monolithic compliant structures that are otherwise unachievable with traditional manufacturing. Strategic partnerships with technology providers such as Stratasys and 3D Systems can accelerate prototyping and reduce time-to-market.

- Target High-Growth Sectors: Focus on applications in minimally invasive surgical tools, precision optics, and aerospace actuation systems, where compliant mechanisms deliver clear performance and cost advantages. According to MarketsandMarkets, the medical device and aerospace sectors are projected to see above-average CAGR in compliant mechanism adoption through 2025.

- Enhance Simulation and Design Capabilities: Investment in advanced simulation software and topology optimization tools is critical. These tools, offered by companies like ANSYS and Autodesk, enable engineers to optimize compliant mechanism designs for specific load cases and operational environments.

Investment Insights:

- Venture Capital and M&A Activity: The compliant mechanisms space is attracting increased venture capital, particularly in startups focused on MEMS and biomedical devices. Strategic acquisitions by established engineering firms are expected to intensify as the technology matures.

- Intellectual Property (IP) Portfolio Development: Building a robust IP portfolio around novel compliant mechanism designs and manufacturing processes will be a key differentiator and value driver for both startups and incumbents.

- Global Expansion: Companies should consider expanding into Asia-Pacific markets, where precision engineering and electronics manufacturing are experiencing rapid growth, as noted by Grand View Research.

In summary, the compliant mechanisms market in precision engineering is set for robust growth in 2025, driven by technological innovation and expanding application areas. Strategic investments in materials, manufacturing, and design capabilities will be essential for capturing emerging opportunities and sustaining competitive advantage.

Sources & References

- MarketsandMarkets

- Society of Manufacturing Engineers

- NASA

- Statista

- American Society of Mechanical Engineers

- IEEE

- Physik Instrumente (PI)

- Boston Micromachines Corporation

- MicroSure

- Carl Zeiss AG

- Massachusetts Institute of Technology (MIT)

- ETH Zurich

- Grand View Research

- Frost & Sullivan

- European Commission

- Mordor Intelligence

- Stratasys

- Nature Reviews Materials

- Sandvik

- DuPont

- 3D Systems